Vertical growing, or controlled environment agriculture (CEA), is the combination of automation technology and traditional farming. With climate volatility increasing the frequency of droughts or floods and population growth encroaching on more farmland, traditional in-ground crop farming has many challenges. By incorporating an indoor growing environment, the odds of success are much higher and can increase our food security in the U.S. While increased yields and food security are benefits of indoor growing, energy and labor costs present challenges.

Common dirtless indoor growing takes place in glass walled greenhouses, sunless structures or hybrids of the two using some form of hydroponics, LED lighting and advanced HVAC solutions. This market segment is about 10 years old in the U.S. and has been the recipient of millions of dollars of investment. Early adopters required a huge influx of capital to support the development of growing infrastructure, farm site design and determination of optimal crops by location. They must also market their product, establish off takers, set up distribution models and hire talented teams for both R&D and growing product.

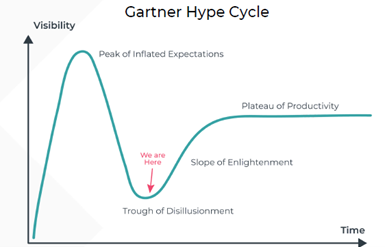

The Gartner Hype Cycle is often referenced as a way to represent the lifecycle stages encountered by an emerging technology from initial development to adoption. As depicted by the chart below, the vertical growing market is at the end of the first phase for a new segment. Several companies have proven they can successfully grow various crops indoors with exceptional yields, but few of them are operating with a positive cash flow without continued investments. 2022 was a rough year for the venture capital world; many investments in the CEA market dried up, and so too did many companies. Some companies have closed their doors, many have delayed or cancelled existing projects and others have changed their business models to focus on profitability rather than expansion.

EnTech Solutions is a division of FTI, and along with our sister companies, Faith Technologies and Excellerate, we can design, develop and manufacture comprehensive energy solutions to address vertical growers’ immediate energy needs while keeping a focus on the future. Our Path to Smarter Energy™ is a step-by-step energy guide that includes simple energy conservation all the way through achieving energy independence, aligned with your financial, operational and environmental goals along the way.

Costs Associated with Indoor Vertical Growing

Energy is the single largest cost for indoor growing and the costs continue to trend upward, so creating a plan to address energy usage is the first step. If you don’t know where your energy is being consumed, adding monitoring and metering devices to your infrastructure will help find the heavy users. Our engineers work with your team to retrofit metering into your current farm or design metering into your new farm’s infrastructure. By pinpointing the cause of the usage, we look at energy conservation solutions to reduce the load. With the metered data, we can track any carbon reduction goals the company has established. After the waste has been eliminated or reduced, we look at new energy generation means like solar, wind, CHP or others. Adding a renewable source of energy can significantly lower operating costs while making your overall farm more sustainable. If resiliency is an issue or need, we can incorporate battery energy storage solutions or a microgrid for a state-of-the-industry solution to reach a net-zero operation.

The second largest vertical growing operating cost is labor. One advantage of indoor growing is that fewer people touch the product, therefore creating a safer product and reducing bacteria outbreaks like listeria, salmonella or norovirus. The best way to reduce both human contact and labor costs is by using automation. This approach can’t be an afterthought; it needs to be a holistic approach to growing modernization planned ahead of construction.

Developing a road map that outlines your most critical areas of exposure enables:

- A methodical approach to improvement while controlling costs to fit your budget.

- Lower total cost of ownership (TCO) by replacing the technology that is becoming increasingly more challenging to support (acquiring spare parts, finding qualified technical personnel to assist and maintain, etc.).

- Increased production efficiency and managed risk by aligning objectives with technology.

While there are some established manufacturers of equipment designed for functions like seeding, harvesting, packaging and conveyance, tying them together into an existing system can be daunting. EnTech Solutions can truly benefit the CEA market with our full-solution approach to system integration, combining all the required elements of vertical growing into one unified solution. Designing and engineering systems based on the growers goals, then manufacturing them off-site, reduces build time and costs while increasing quality and safety. Our holistic approach to energy design, monitoring, conservation, generation and storage increases sustainability and resilience. Contact us today to discuss your vertical growing needs.

Thank you for checking out the EnTech Solutions blog. To stay up to date with technologies, developments and trends about clean energy, please subscribe.